The Future of Accuracy Measurement: Recognizing the Function of 3D Laser Scanning Technology

The landscape of precision dimension is developing with the arrival of 3D laser scanning innovation. This development guarantees improved precision and effectiveness throughout different fields. As industries begin to welcome these developments, the implications for project management and implementation become significantly significant. The transformative results of this technology prolong beyond simple numbers and dimensions, hinting at a broader change in just how specialists approach their job. What might this mean for the future?

What Is 3D Laser Scanning Modern Technology?

3D laser scanning modern technology is a sophisticated technique made use of to catch precise three-dimensional measurements of physical items and settings. This modern technology uses laser beam of lights to gather information factors, which are after that processed to develop comprehensive electronic depictions of the scanned topics. By discharging hundreds of laser pulses per second, 3D laser scanners can accurately tape the form, dimension, and spatial relationships of different surface areas.

The procedure commonly entails placing the scanner at various vantage factors to record extensive data. The resulting point cloud, a collection of numerous information factors, can be assessed and transformed right into 3D models. Applications of this modern technology span numerous areas, consisting of design, architecture, and heritage conservation, where it helps in paperwork and analysis. As a non-intrusive method, 3D laser scanning decreases disruption to the atmosphere, permitting extensive evaluations of both existing structures and all-natural landscapes, therefore boosting understanding and assisting in notified decision-making.

Key Benefits of 3D Laser Scanning in Numerous Industries

3D laser scanning technology supplies considerable advantages throughout numerous sectors by supplying enhanced precision and precision in dimensions. This modern technology not just enhances workflows yet likewise causes considerable time and expense financial savings. As companies increasingly embrace this innovative approach, the advantages become obvious in improved project results and efficiencies.

Improved Accuracy and Precision

The integration of laser scanning modern technology has reinvented the method sectors approach dimension and data collection. This innovation offers an unprecedented level of precision, capturing countless information points in a solitary scan. As a result, specialists across numerous areas, such as manufacturing, design, and architecture, can produce very detailed 3D designs that reflect real-world problems. Boosted precision reduces errors linked with traditional measurement techniques, ensuring that layouts and constructions are based upon accurate data. Additionally, the capability to catch detailed details allows for better analysis and decision-making, eventually bring about improved outcomes. By leveraging 3D laser scanning, industries can accomplish higher standards of high quality, making it an invaluable tool for accurate measurements.

Time and Cost Efficiency

Effectiveness in time and expense is a considerable advantage provided by laser scanning technology, transforming job execution across various industries. By swiftly capturing in-depth 3D information, laser scanning decreases the moment invested on manual dimensions and lessens the threat of errors. This quick information acquisition facilitates much faster decision-making and task timelines, enabling teams to allocate sources a lot more successfully. Furthermore, the technology lowers the demand for rework, as exact designs lead to far better preparation and implementation. Industries such as building and construction, architecture, and manufacturing advantage considerably, seeing lower costs associated with labor and materials. In general, 3D laser scanning not just improves operational performance however likewise contributes to substantial savings, making it an important device in today's affordable landscape.

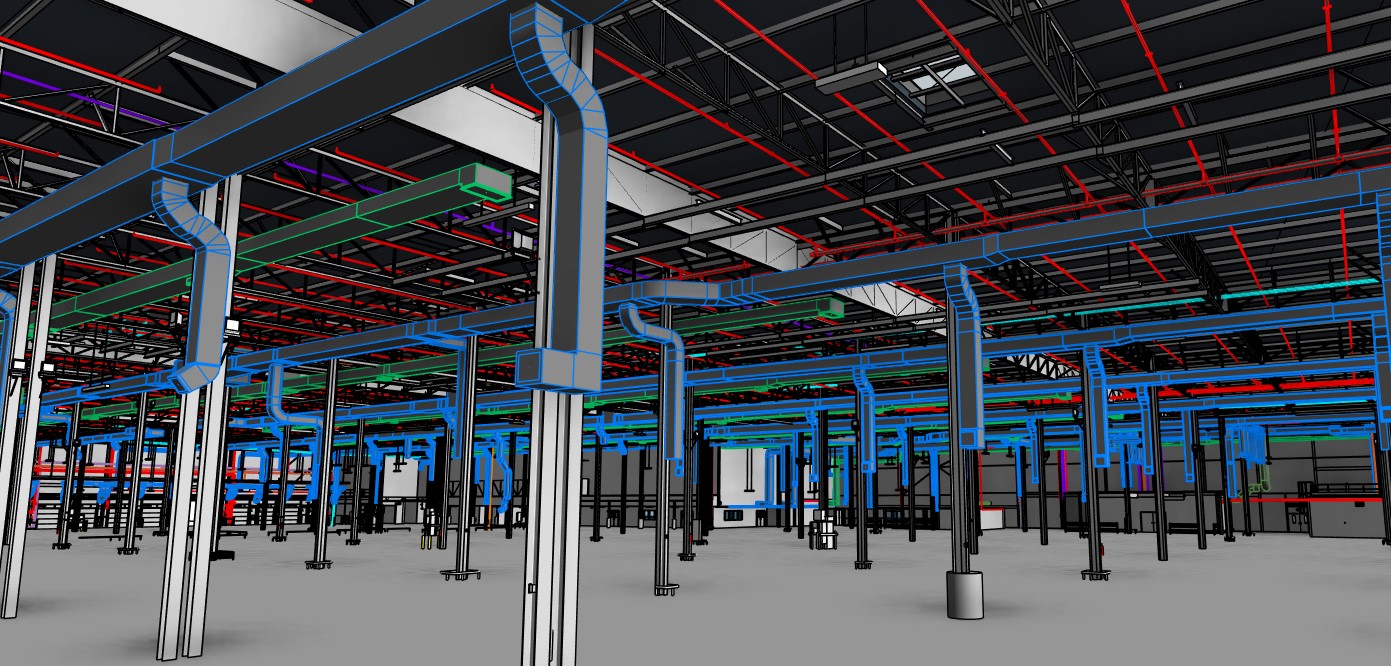

Applications of 3D Laser Scanning in Design and Construction

As building and construction projects expand progressively complex, the adoption of laser scanning modern technology has actually arised as a transformative solution. This innovation supplies precise dimensions and detailed 3D depictions of existing frameworks, facilitating more exact preparation and style procedures. Architects utilize 3D laser scanning to produce electronic designs that capture intricate details, making sure that renovations and new building and constructions line up flawlessly with existing problems.

The Role of 3D Laser Scanning in Manufacturing Processes

3D laser scanning plays an essential function in making processes by improving top quality control through exact dimensions and data collection. This innovation permits manufacturers to determine disparities early, minimizing errors and waste. Furthermore, it enhances manufacturing workflows by helping with far better communication and coordination among teams.

Enhanced Quality Control

Quality assurance in making procedures has been reinvented by the combination of laser scanning technology. This ingenious strategy permits specific dimensions and detailed inspections of components, guaranteeing that they satisfy strict high quality requirements. 3D laser scanning catches elaborate geometries and resistances, making it possible for producers to discover discrepancies from layout requirements promptly. This modern technology substantially lowers human mistake related to traditional dimension approaches, supplying trustworthy and constant data. By facilitating real-time quality guarantee, it allows aggressive modifications in the manufacturing procedure, inevitably resulting in improved item reliability and consumer fulfillment. As sectors progressively take on 3D laser scanning, the capacity for improved quality assurance ends up being apparent, noting a transformative shift in making methods.

Streamlined Manufacturing Process

Effective production operations are progressively gaining from the assimilation of laser scanning innovation in manufacturing procedures. This technology enables fast, accurate measurements of parts and settings up, considerably minimizing the time required for setup and modifications. By capturing exact geometry, producers can promptly recognize disparities between style requirements and actual items, making it possible for instant rehabilitative actions. Additionally, 3D laser scanning facilitates the seamless transfer of data in between style and manufacturing teams, improving cooperation and decreasing mistakes. The innovation likewise supports digital twin try this out production, allowing for real-time tracking and optimization of manufacturing procedures. Therefore, companies can attain higher performance, lowered waste, and improved overall productivity, eventually driving affordable benefit in the marketplace.

Preserving Heritage: Exactly How 3D Laser Scanning Aids Cultural Preservation

As cultural heritage sites face the danger of deterioration and destruction, ingenious modern technologies such as laser scanning emerge as necessary devices for preservation initiatives. 3D laser scanning catches elaborate information of historic frameworks and artefacts with remarkable precision, developing electronic versions that offer numerous objectives in conservation. These versions allow for accurate documentation of current problems, making it possible for specialists to keep track of changes in time and evaluate wear and tear risks.

Furthermore, laser scanning assists in online remediation, helping conservators develop prepare for fixings or recreating lost components without intrusive approaches. The modern technology likewise helps in educating the general public, providing immersive experiences with virtual scenic tours that highlight the value of these websites. By explanation integrating 3D laser scanning into social conservation practices, stakeholders can assure that heritage is maintained for future generations while improving understanding and gratitude of historical contexts.

The Future Expectation: Innovations and Patterns in 3D Laser Scanning Innovation

3D laser scanning technology has actually currently transformed numerous industries, its future assurances even higher advancements that will certainly enhance availability, rate, and accuracy. Arising fads indicate a boost in assimilation with synthetic knowledge and artificial intelligence, causing smarter data processing and evaluation capacities. This synergy will allow quicker decision-making and even more precise results in fields such as heritage, construction, and engineering conservation.

Improvements in hardware are anticipated to generate lighter, a lot more mobile scanning gadgets, equalizing accessibility for smaller sized firms and individual professionals. As software continues to evolve, user-friendly applications will certainly streamline intricate operations, making 3D scanning a lot more easily accessible to non-experts

The increase of cloud-based services will help with real-time collaboration and information sharing amongst stakeholders, paving the means for structured job administration. Collectively, these trends signify a future where 3D laser scanning innovation becomes a necessary tool in an even more comprehensive spectrum of applications.

Frequently Asked Concerns

Just How Much Does 3D Laser Scanning Technology Price?

What Are the Skills Called For to Run 3D Laser Scanners?

Running 3D laser scanners calls for technological effectiveness, focus to information, spatial recognition, expertise of software program for information handling, and an understanding of checking concepts. Furthermore, strong analytical skills and problem-solving abilities are crucial for reliable procedure.

Can 3D Laser Scanning Integrate With Other Technologies?

Yes, 3D laser scanning can incorporate flawlessly with various other innovations, such as Geographic Info Systems (GIS), Building Info Modeling (BIM), and increased truth, improving data precision and assisting in improved analysis across numerous markets and applications. - 3D Scanning

What Is the Normal Scanning Variety Of These Instruments?

The typical scanning series of 3D laser scanning gadgets varies extensively, usually in between 50 meters to over 1,000 meters, depending upon the model and application, affecting their suitability for different precision dimension tasks and settings.

For how long Does a 3D Laser Scanning Task Take?

A 3D laser scanning task normally takes anywhere from a few hours to numerous days, relying on variables such as job size, intricacy, and needed detail. Each project's timeline can vary significantly based on these components.

The landscape of precision dimension is developing with the arrival of 3D laser scanning innovation. 3D laser scanning modern technology is an advanced approach utilized to capture exact three-dimensional dimensions of physical items and settings. 3D laser scanning technology provides considerable click for source advantages throughout various markets by giving enhanced precision and precision in dimensions. 3D laser scanning modern technology has currently changed various industries, its future assurances even higher advancements that will improve availability, precision, and rate. 3D laser scanning modern technology usually sets you back in between $10,000 and $100,000, depending on the tools's capacities and features.